PVC Qhov Rooj thiab Qhov rai Profile Extrusion Kab

Kev ntsuas qhov project

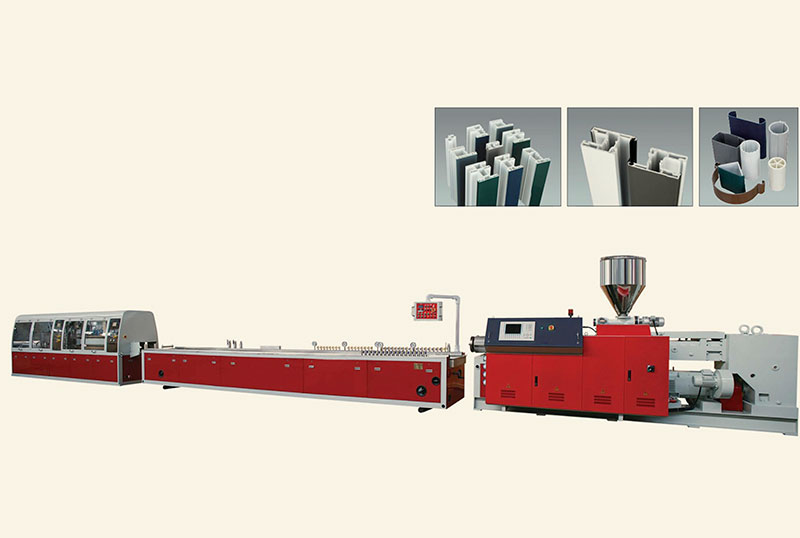

Raws li koj xav tau, peb xav kom peb SJZ65/132 PVC Profile Extrusion Kab.Cov kab extrusion no yog tsim los ntawm SJZ65/132 Conical Twin-screw Extruder thiab downstream pab tshuab.Thov xyuas cov ntaub ntawv hauv qab no:

1.1 Cov yam ntxwv ntawm cov khoom

1.1.1 Raws li cov khoom siv:

- PVC hmoov:

- CaCO 3:

1.1.2 Additive:

- Kev sib txuas

- Lubricant

- 1.1.3 Cov ntaub ntawv

- Tag nrho cov khoom yuav tsum tau tov tag nrho.

Cov khoom tiav: PVC Profile;

Cov zis muaj peev xwm: 150 ~ 250kg / hr (nyob ntawm cov khoom tiav

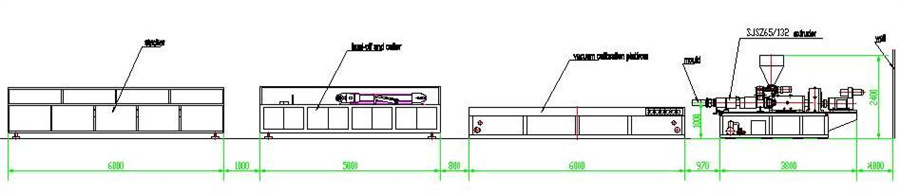

Tag nrho cov kab ntau lawm suav nrog:

yas hmoov ntsia hlau loader → SJSZ65/132 conical ntxaib ntsia hlau extruder → Pwm → Calibrator rooj → Haul tawm tshuab → Txiav tshuab → 6meters stacker

Technical specification

SJZ65/132 PVC Profile extrusion kab

| Tsis muaj. | Lub npe | Yees duab ntawm lub tshuab | Qty. | Technical specifications | |

| 1 | ZJ300 feeder |  | 1 | Rated kis tau tus mob: 300kg / h | |

| Lub cev muaj zog: 1.5kw Caij nplooj ntoos hlav txoj kab uas hla: Φ36mm Khoom siv: Stainless hlau | |||||

| 2 | SJZ65/132 conical ntxaib-ntsia hlau extruder |  | 1 | 2.1 hli 2.2 cev 2.3 tsav lub cev muaj zog 2.4 pub system 2.5 Lub tshuab nqus tsev vacuum 2.6 Adapter 2.7 Main hluav taws xob txee Kev tiv thaiv tus kheej | |

| 2.1 Ntsia Hlau:Txoj kab uas hla conical 65/132 mm rau PVC drainpipe thiab dej muab tub. Khoom siv ntawm cov ntsia hlau: 38CrMoAl Kev kho deg: Nitriding ua, thickness: 0.6 ~ 0.8mm, Polishing Rotating ceev (counter rotating): 1-34.7 rpm / min 2.2 chim: txoj kab uas hla conical 65/132 Kev ua haujlwm sab hauv: nitrided nrog thickness: 0.6 ~ 0.8mm Qhov chaw cua sov: 4 Cua sov hom: Cam khwb cia alumina + stainless hlau npog Lub zog cua sov: 22kw Txias hom: Cua kiv cua: 3 Teeb 2.3 Tsav lub cev muaj zog: Lub cev muaj zog: 37Kw Hom lub cev muaj zog = AC 2.4 Pub System: Lub ntiajteb txawj nqus thiab ntsia hlau dosing feeding system Nrog stainless hlau hopper Dosing feeding system: Lub cev muaj zog: 1.5Kw Pub lub tes tsho nrog lub voj voog dej txias 2.5 Lub tshuab nqus tsev dehumidifying: Lub tshuab nqus tsev twj: 1set Lub tshuab nqus tsev kawm ntawv = 0 ~ 0.075 Mpa 2.6 Adaptor: (Tshooj Interflow): Khoom siv: #40steel Chrome plated, puab convergent flow type Txoj kev txuas nrog tuag: clamping thaiv + ntsia liaj qhov rooj Siab melt sensor thiab thermocouple 2.7 Cov khoom siv hluav taws xob tseem ceeb: Inverter: ABB lossis DELATA Contactor: Schneider los yog SIEMENS Cua Hloov: Schneider Relay: Omron Kub tswj: RKC 2.8 Kev tiv thaiv tus kheej: Tshaj tam sim no tiv thaiv lub cev muaj zog Tshaj siab tiv thaiv ntawm cov ntsia hlau. | |||||

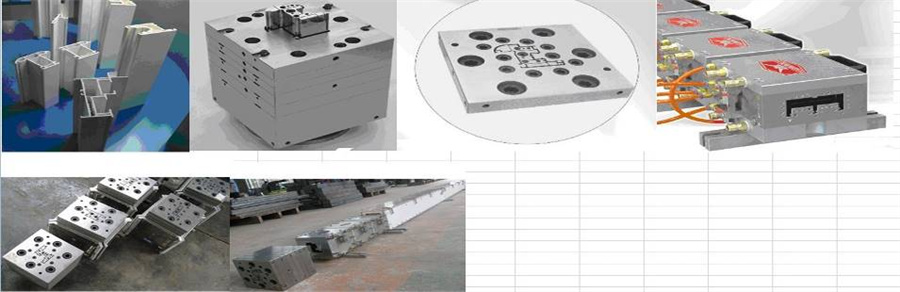

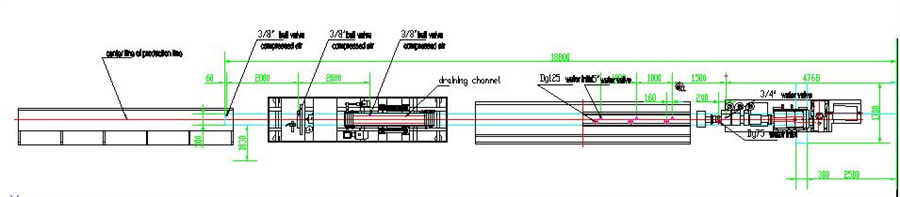

| 3 | YF240 Calibration platform |  | 1 | 3.1 Sab nrauv Dimension 3.2 Lub tshuab nqus tsev twj 3.3 Lub tshuab nqus dej 3.4 Peb txoj kev hloov kho: Cov dej sib cuag yog tsim los ntawm stainless hlau. | |

| 3.1 Sab nrauv Dimension: Lx W x H: 6000x1100x1000mm (adjustable) 3.2 Lub tshuab nqus tsev vacuum: Lub tshuab nqus tsev twj tso kua mis: 3x5.5KW; Keeb kwm: Yuanli, Suav teb 3.3 Lub twj tso kua mis: Dej twj tso kua mis: 1 × 4KW; Keeb kwm: Guangzhou, Suav teb 3.4 Peb txoj kev hloov kho: Pem hauv ntej thiab rov qab nrog 0.75 Kw lub cev muaj zog Ntev: ± 1000mm Up thiab down, sab laug thiab txoj cai manually kho Ntau yam: nce thiab nqis: ± 150mm Sab laug thiab txoj cai tsiv: ± 50mm | |||||

| 4 | DYⅢQ Haul-off thiab cutter (ua ke) |  | 1 | 4.1 Kev khiav tawm 4.2 Cutter | |

| 4.1 Kev khiav tawm Kev khiav ceev: 0-3m / min; Lub cev muaj zog: 5.5KW; Kab ntsig dav: 210mm; Kab ntsig ntev: 2200mm; Pneumatic clamp; Txais holip lossis ABB inverter; 4.2 Cutter Lub cev muaj zog: 2.2KW; Cov khib nyiab sau lub cev muaj zog: 1.5KW; Txoj kab uas hla: 500mm; Txiav ntau yam: 200mm; Nrog cov khoom siv khib nyiab; | |||||

| 5 | Tipping rooj |  | 1 | 5.1 Tipping Table: Ntev Tswj txoj kev Qhov siab kho qhov ntau | |

| Ntev:6,000 hli Tswj txoj kev:Pneumatic Nrog screws los kho qhov siab ntau:0 ~ 180 hli | |||||

6. Cov khoom siv sib xyaw

1. Daim ntawv thov:

Sib tov raw khoom

2. Cov zis: ≤500

3. Cov khoom siv:

① kub tov khoom

② txias tov khoom

③ autoloader

4. Parameter

| Qauv | / | SRL-Z300/600 mixer pawg | ||

| ||||

| 1 | Kub tov khoom | |||

| 2 | tag nrho ntim ntawm kub tov khoom | L | 300 | |

| 3 | zoo ntim ntawm kub tov khoom | L | 225 | |

| 4 | khoom hnyav / batch | ㎏/batch | ≤100 | |

| 5 | Tso zis | ㎏/h | ≤500 | |

| 6 | lub cev muaj zog | KW | 40/55, ob chav ceev lub cev muaj zog | |

| 7 | cua sov zog | KW | 12 | |

| 8 | kub tov khoom rotating ceev | r / min | 475/950 ib | |

| 9 | Qhov ntau ntawm stirring hniav | pcs | 3 (1Cr18Ni9Ti) | |

| 10 | sib tov lub sij hawm | min/batch | 8-10 | |

| txias tov khoom | ||||

| 1 | txias mixer ntim | L | 600 | |

| 2 | zoo ntim ntawm cov khoom cua txias | L | 450 | |

| 3 | lub cev muaj zog | KW | 11 | |

| 4 | cov khoom ntawm cov khoom cua txias tov khoom | / | ZG1Cr18Ni9Ti | |

| 5 | stirring hniav rotating ceev | r/m | 130 | |

| 6 | nqa tswj txoj kev | / | pneumatic | |

| 7 | Txoj kev ua kom txias | / | dej txias | |

| 8 | lub sijhawm txias | min/batch | 10-12 | |

| Hluav taws xob | ||||

| 1 | AC contactor | / | Schneider | |

| 2 | Kub tswj | / | Omron | |

| Autoloader | ||||

| 1 | Tsheb thauj mus los txoj kab uas hla | mm | 101 | |

| 2 | Charge lub cev muaj zog | KW | 1.5 | |

| 3 | Push khoom lub cev muaj zog | KW | 0.55 ib | |

| 4 | Cia ntim | kg | 80 | |

| 5 | Cov khoom siv ntawm lub hopper thiab lub raj | / | Stainless hlau | |

7 Yas crusher (yeem)

Daim ntawv thov: crushing pov tseg PVC seem rau kev siv dua

| qauv | SWB-400 |

| |

| Txoj kab uas hla ntawm Rotating hniav | 400 hli |

| Rotating hniav kom muaj nuj nqis | 5 |

| Rotating ceev | 500r / min |

| Taag hniav kom muaj nuj nqis | 2 |

| Aperture ntawm qhov screen (mm) | 10 |

| Crushing muaj peev xwm | 350-450 kg / h |

| Lub zog (kw) | 13.2 |

| Pub lub qhov ncauj (mm) | 375 * 320 |

| Qhov hnyav (kg) | 980 ua |

| Loj (mm) | 2500 * 1200 * 2000 hli |

8. PVC pulverizer (yeem)

Daim ntawv thov: grind crushed PVC pieces rau hauv hmoov

| |

| Txoj kab uas hla ntawm crushing chav (mm) | 400 |

| Tus naj npawb ntawm rotor | 3 |

| Main ncej ceev (r / min) | 3400-3700 Nws |

| Lub cev muaj zog (kw) | 30 |

| Cov zis muaj peev xwm (kg / h) | 50-150 |

| Qhov hnyav (kg) | 1000 |

Flow kab thiab configuration rau PVC profile ntau lawm kab

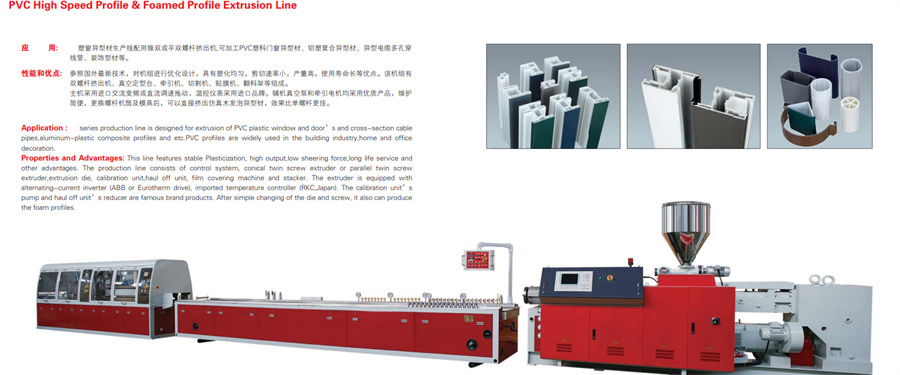

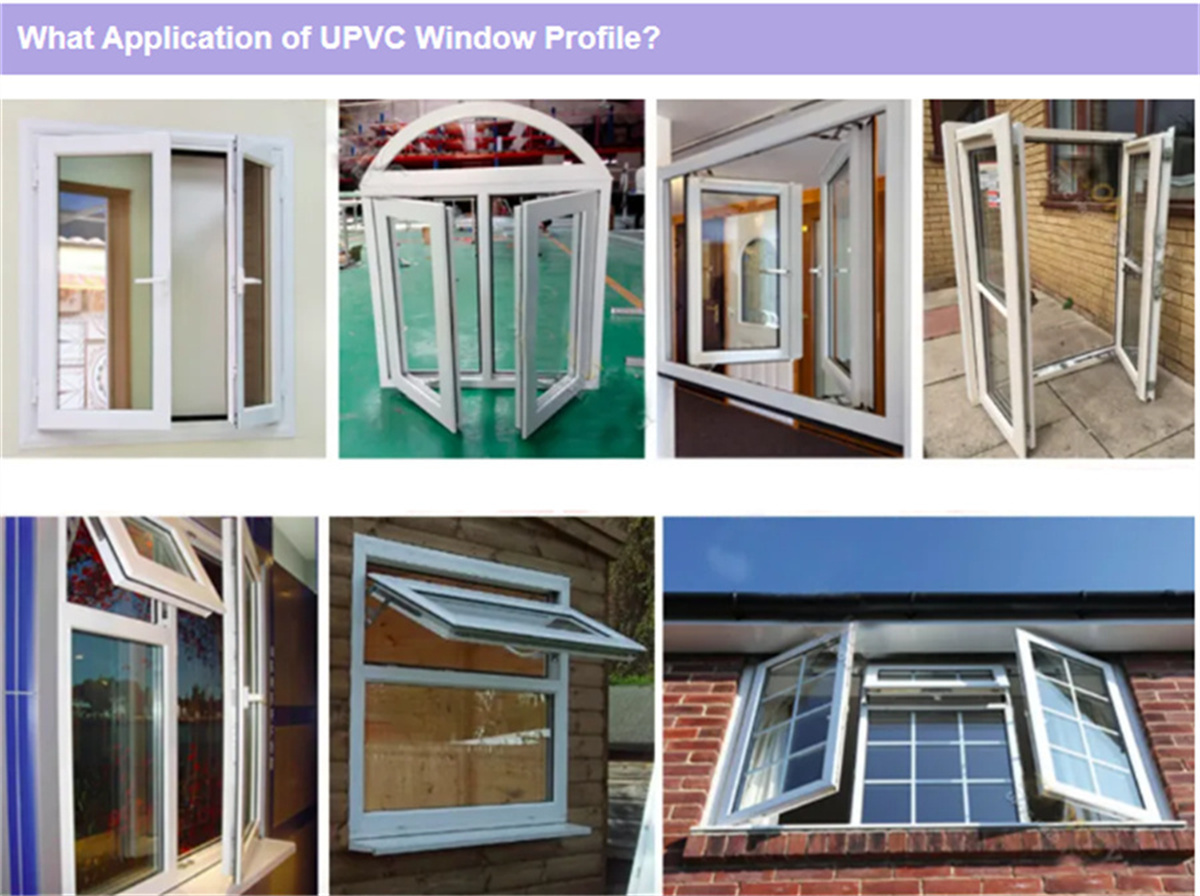

Daim ntawv thov

Muab faib raws li qhov qhib hom:

Tsau qhov rais, qhov rais sab sauv ncua kev kawm ntawv, nruab nrab ncua kev kawm qhov rais, qis dai qhov rais, ntsug qhov rais, tiaj qhib qhov rais, pulley tiaj qhov rais, pulley qhov rais, tiaj qhib qhov rooj thiab qhov rais, zawv zawg qhov rooj thiab qhov rais, thawb lub qhov rais folding, hauv av caij nplooj ntoos hlav qhov rooj, nqa qhov rooj zawv zawg, thawb rub lub qhov rooj, sab hauv rov qab zawv zawg qhov rooj.

PVC Profile muaj cov yam ntxwv xws li kev sib cais suab, lub suab nqus, sib cais thaum tshav kub kub, khaws cia kub, thiab lwm yam.Cov khoom yog incombustible, nws muaj kev nyab xeeb rau kev siv.

Tag nrho cov khoom lag luam muaj cov khoom pov thawj noo noo, pov thawj mildew, dej tsis kam, nws cov kev vibration resistant nyhuv yog zoo.Tag nrho cov khoom lag luam muaj cov cuab yeej ntawm huab cua pov thawj, nws cov luster yuav nyob mus ib txhis, nws tsis yooj yim rau kev laus.Cov khoom no yog lub teeb, cia & thauj, kev tsim kho yooj yim dua.Cov khoom no tuaj yeem ua haujlwm nrog cov cuab yeej ib txwm siv rau cov khoom siv ntoo.Drilling, sawing, ntsia thawv, npaj, sib txuas tuaj yeem ua tau zoo li cov khoom siv ntoo.Nws yog tsim rau thermal shaping, thermal bending thiab fold ua.Nws tuaj yeem welded, nws tuaj yeem txuas nrog lwm yam khoom siv PVC.Qhov saum npoo ntawm cov khoom no yog du, nws tuaj yeem luam tawm.