PE Carbon Composite Kauv Yeeb Nkab Extrusion Kab

Lub ntsiab technical parameter

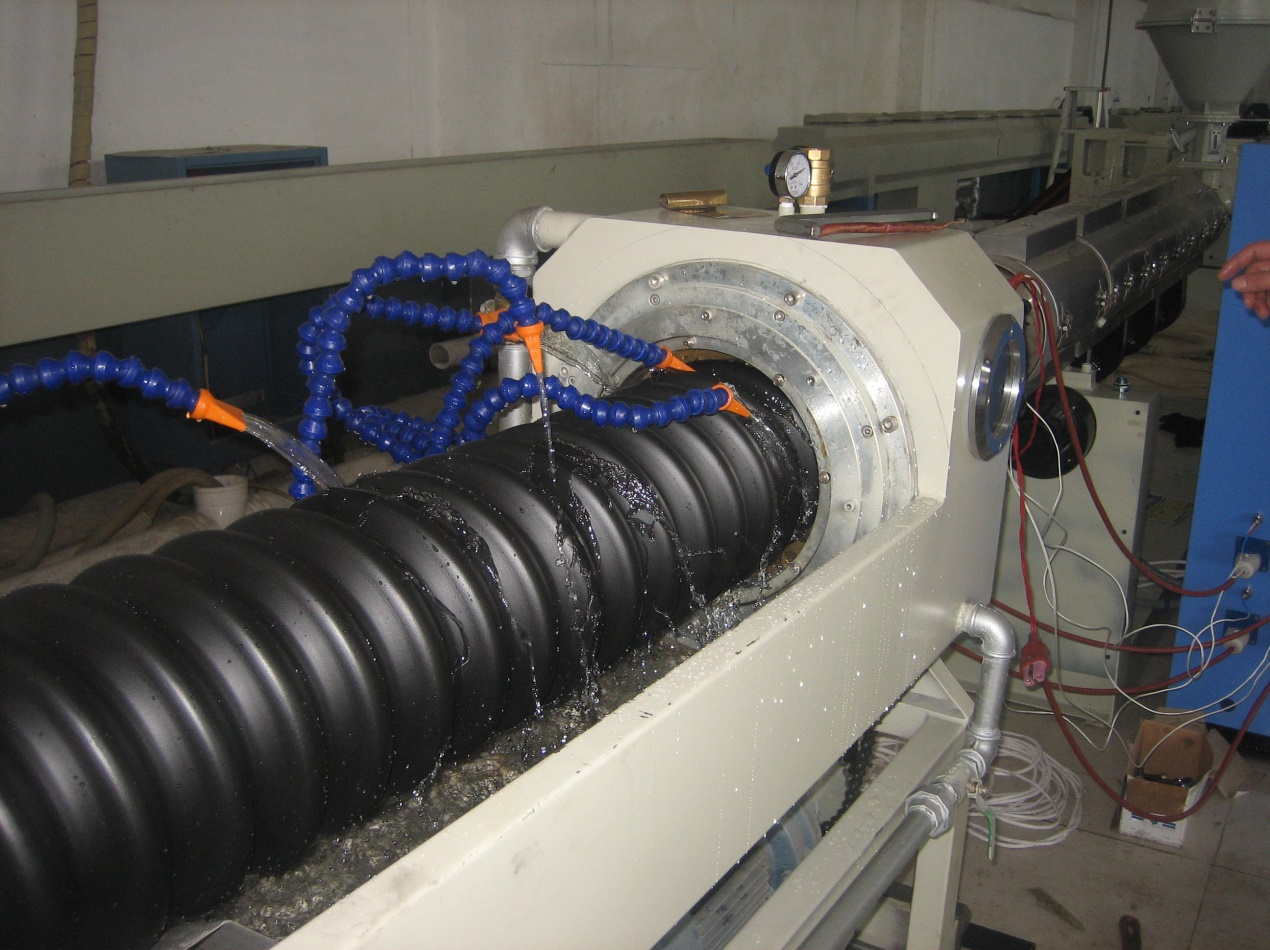

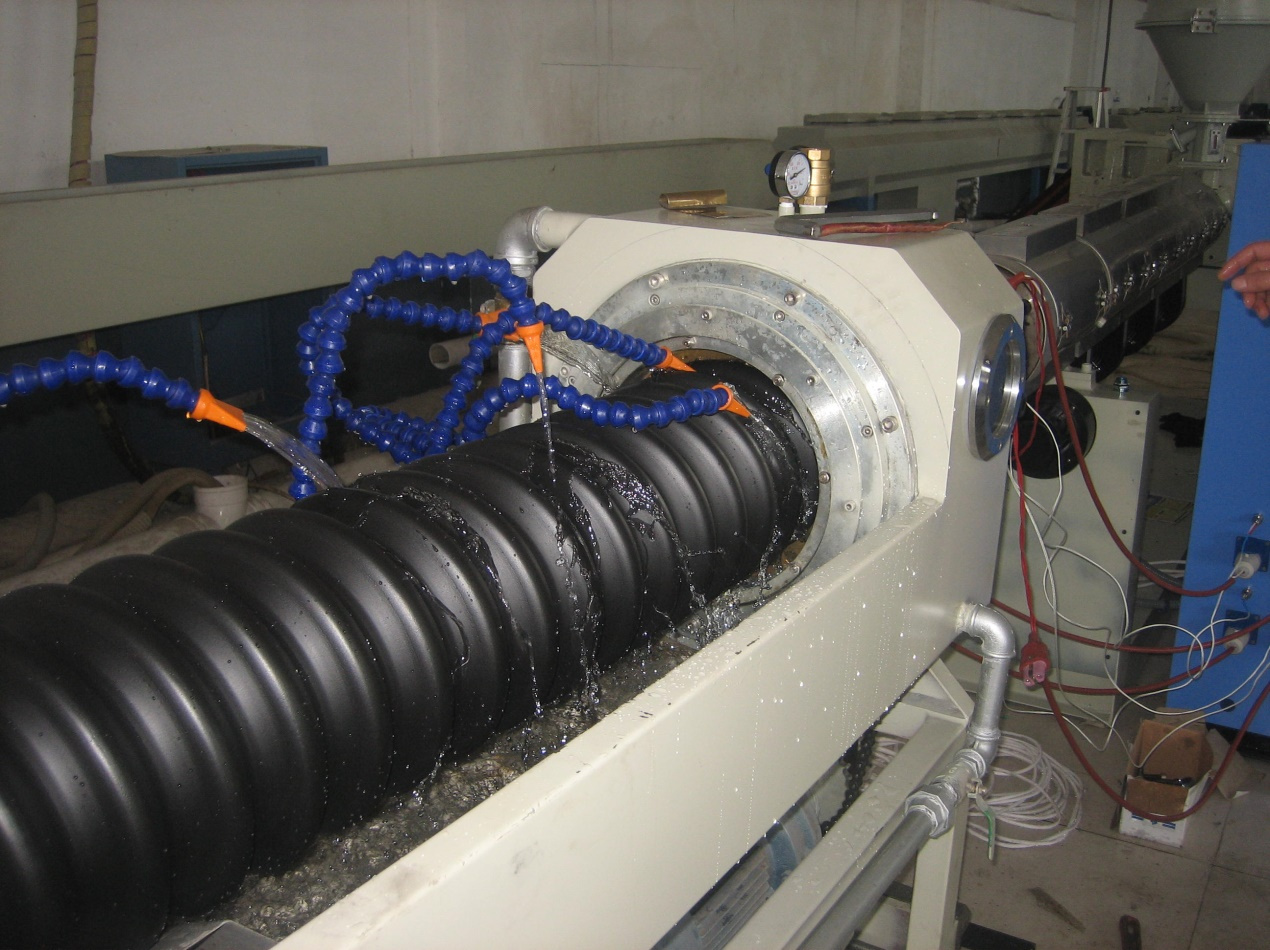

Cov khoom siv kauv corrugated yeeb nkab muaj cov qauv tshwj xeeb ntawm lub cev, cov yeeb nkab cov khoom siv tshuab ua haujlwm zoo, lub zog compressive, cov yeeb nkab faus rau hauv deformation, sab hauv kauv uniform cable nyob ib ncig ntawm cov cua txias efficiency thiab zoo tiv thaiv kev ruaj ntseg ntawm cable.

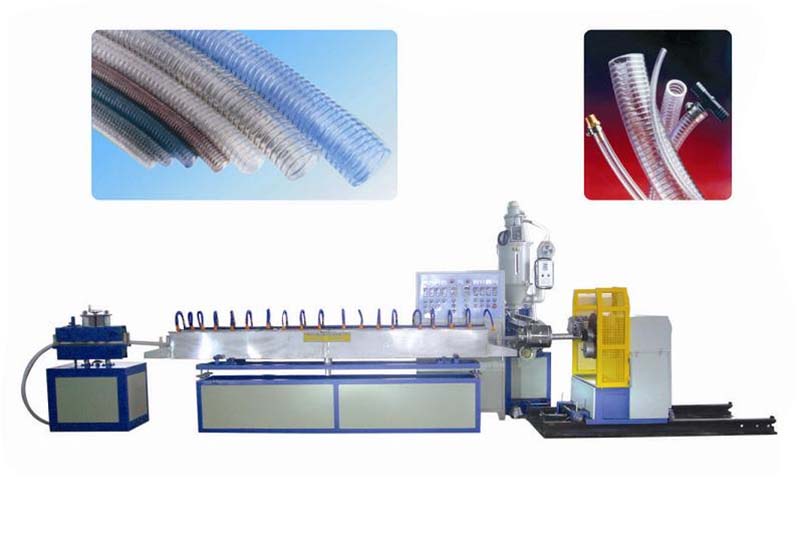

Tsis tas li ntawd, pe kauv yeeb nkab tshuab los ntawm kev hloov lub tes tsho tuaj yeem tsim cov pa roj carbon spiral yeeb nkab tshuab

I. Main Tshuab SJ-65/30 Ib leeg-ntsia hlau extruder 1 unit

Screw txoj kab uas hla Φ65mm

L/D 30:1

Cov khoom siv ntsia hlau 38CrMoALA zoo alloy steel, nitriding, kho deg

Cov khoom siv hluav taws xob 38CrMoALA zoo tshaj plaws alloy hlau, nitriding, kho deg

Ntsia hlau daim ntawv ob-kauj ruam tshwj xeeb tiv thaiv npo BM-hom compounding tsim

Them hom atuomatic nqus plua plav

Iav hloov mechanism kab rov tav hom iav reducer (ua hauv Jiangying Reducer Factory)

Tsis paub meej zaus lub cev muaj zog Huali hauv Shandong

Lub cev muaj zog 45KW

Ceev tswj hom zaus tswj (Fuji ua nyob rau hauv Nyiv)

Tsawg-voltage apparatus ua nyob rau hauv Suav teb

Kub maub los RKC hauv Nyiv

Charging chim cua sov cam khwb cia txhuas hluav taws xob rhaub

Cua sov thiab tshuab cua txias ntu ntu 4

Cua sov zog 25KW

Txoj kev ntawm kev tswj qhov kub thiab txias digital kev txawj ntse tsis siv neeg kub tswj

Max tso zis 100 kg

II.Extruder taub hau 1 set

Cua sov seem ntu 3

Cua sov txoj kev stainless hlau hluav taws xob rhaub

Neck nplhaib pwm kub tswj stepless voltage regulating kub tswj

Cua sov zog 4KW

III.Txoj Kev Tuag 2 sets

Tuag specification φ100mm haum thiab pwm

Tuag daim ntawv helicism

Tuag cov khoom cam khwb cia tooj liab, nto polishing

IV.Pipe Forming Machine 1 unit

Txoj kev nqus txoj kev sib sau

Lub tshuab nqus tsev twj tso kua mis 5.5KW

Centrifugal twj tso kua mis 3KW

Fais fab tuag 3KW

Ceev tswj hom zaus tswj (Fuji ua nyob rau hauv Nyiv)

Azimuth tswj peb qhov kev tswj hwm

V. Hauling Tshuab 1 unit

Max nrug sib nrug 160mm

Siv tau ntev ntev 1200mm

Ceev tswj hom zaus tswj (Fuji ua nyob rau hauv Nyiv)

Lub cev muaj zog 3KW

Hauling daim ntawv roj hmab thaiv hom

Daim ntawv ceeb toom ntxov ntxov

VI.Winding tshuab 1 unit

Winding daim ntawv ib sab tsis siv neeg winding

Tsav hom torque motor

Torque tso zis 10N.M

Peb daim duab xa khoom

Daim ntawv thov

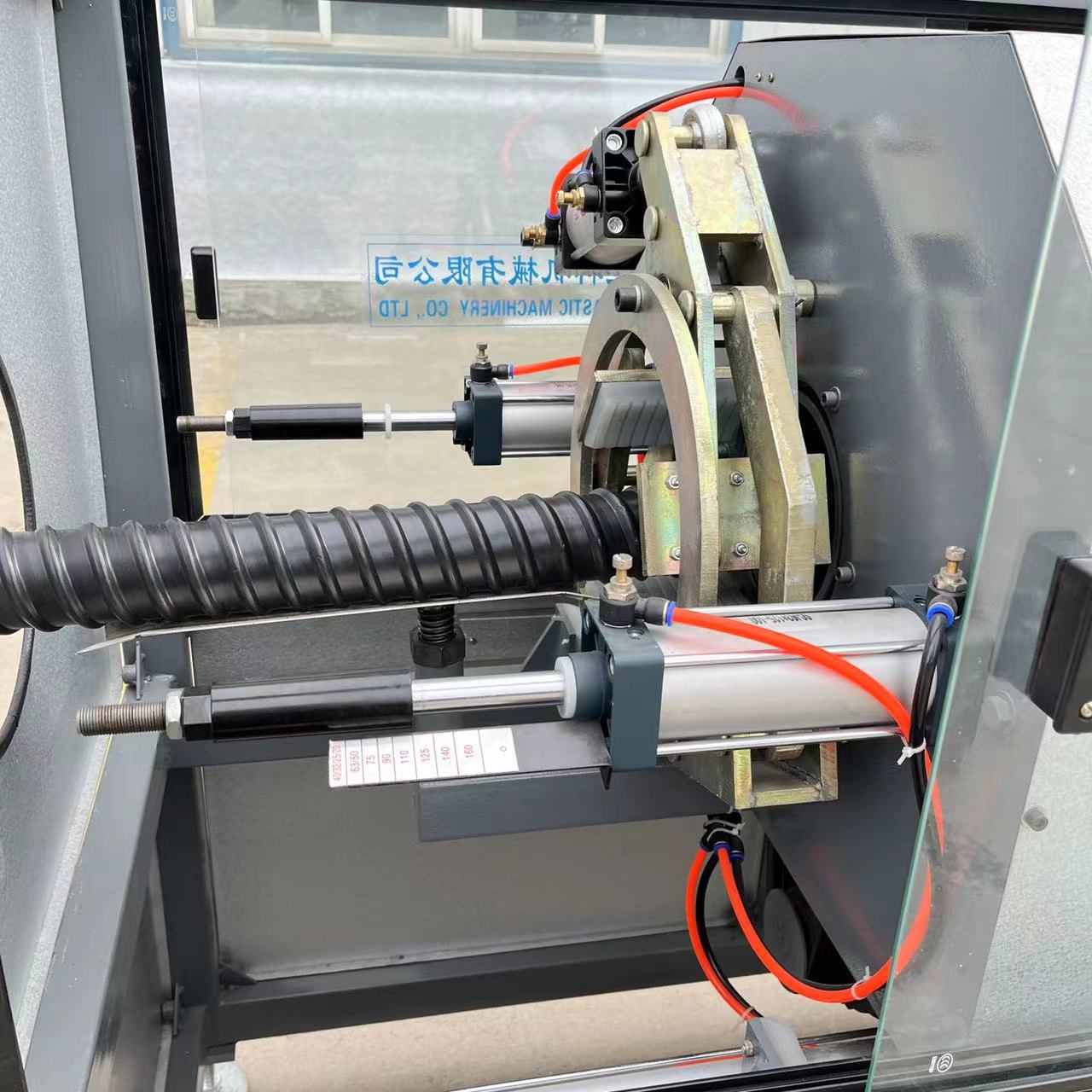

1) Kev txiav ntawm cov khoom tsis tsim cov chips, thiab txiav cov khoom smoothing, yog li txuag cov khoom, cov khoom siv raw, tab sis kuj ua rau cov khoom lag luam nrog cov kav dej sib txuas.

2) Kev txiav cov khoom ntawm cov kab tuaj yeem ua tiav ib txhij txhua lub sijhawm, koj tsis tuaj yeem txiav cov kab ntau lawm txhua lub sijhawm ntawm kev kuaj.

3) Txiav cov txheej txheem du, tsis muaj suab nrov.

4) High automation, siab txiav kom muaj nuj nqis thiab zoo nkauj.