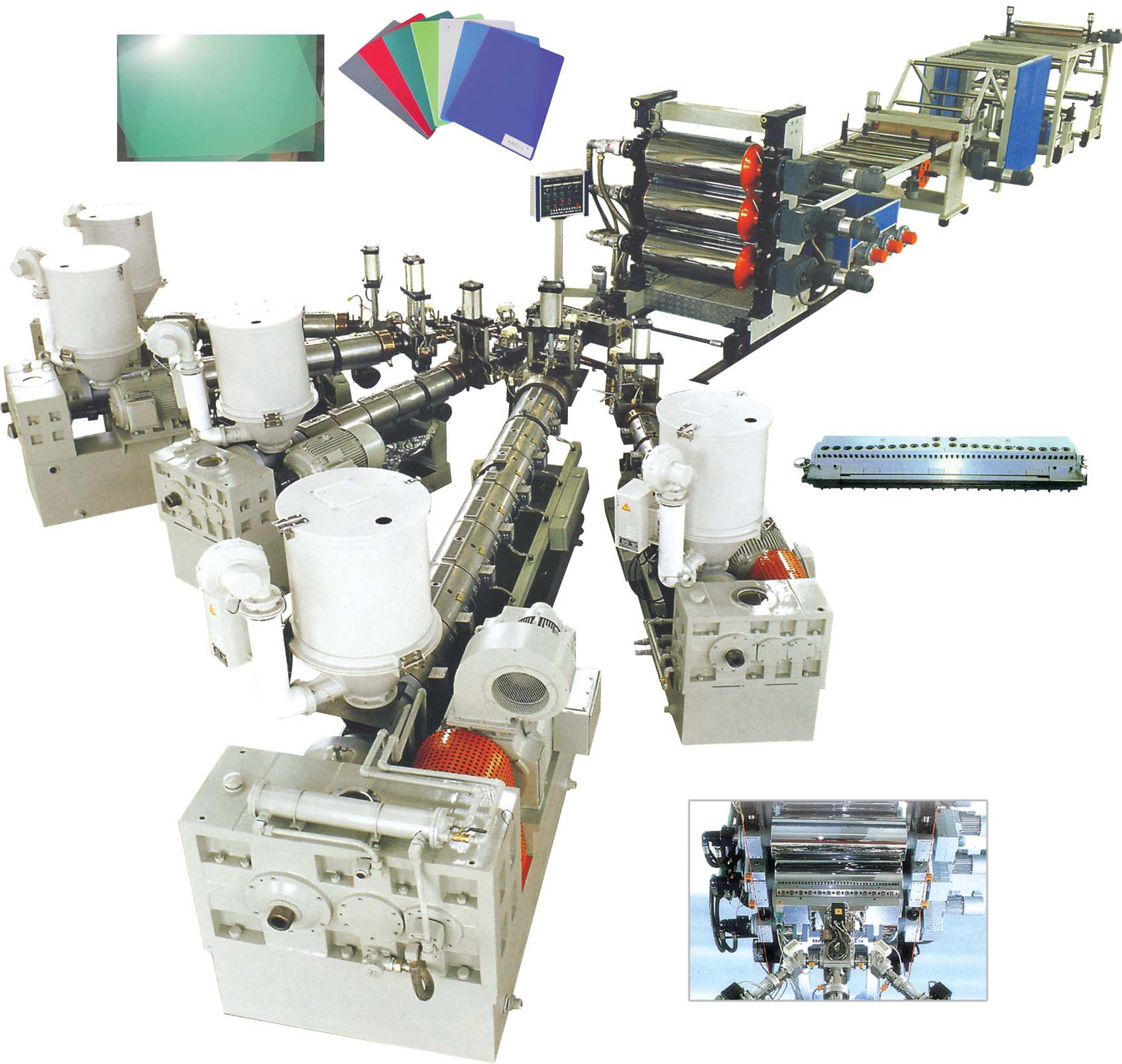

Txog Cov Ntawv Yas lossis Lub Tshuab Board peb tuaj yeem ua tau ntau yam:

ABS HIPS PC PMMA ntawv extrusion kab,

PP / PE / ABS board extrusion kab,

Yas vaj huam sib luag ntawv extrusion kab,

PP hollow profile ntawv extrusion kab,

rigid pob tshab PVC ntawv extrusion kab,

PVC Dawb Foamed Board Extruder Tshuab

WPC Ua Npuas Ncauj Board Extruder Tshuab

PVC Crust Ua Npuas Ncauj Board Extrusion Kab

PVC phab ntsa vaj huam sib luag board tshuab

Peb tshwj xeeb hauv kev tsim PVC WPC ua npuas ncauj tshuab, WPC pem teb tshuab, SPC pem teb tshuab, PVC phab ntsa vaj huam sib luag tshuab, PVC dawb foaming board tshuab.Cov kab no tuaj yeem tsim cov rooj tog zaum rooj tog, vaj huam sib luag vaj tsev, rooj sib tham tshaj tawm thiab cov ntawv hauv pem teb thiab lwm yam.JIASHANG tau tshwj xeeb hauv kev tshawb nrhiav, tsim thiab tsim cov ntawv PVC thiab board tshuab rau ntau tshaj 10 xyoo.Txog tam sim no, nws tau nyob hauv ib qho kev faib ua lag luam loj ntawm cov khoom siv zoo sib xws hauv tsev thiab aboard.Qhov kev loj hlob ntawm pvc ua npuas ncauj board extrusion kab ua pov thawj peb lub tuam txhab txoj kev loj hlob thiab lub zog.Nws kuj yog peb qhov loj tshaj plaws thiab muaj zog tshaj qhov ci ntsa iab hauv cheeb tsam no.Peb kuj yog ib tus neeg xa khoom loj tshaj plaws hauv Suav teb.Peb tau xa tawm ntau tshaj 20 lub teb chaws.

MAIN PARAMETERS ntawm PVC FOAM BOARD:

Dav: 1220mm

Ntev: 2440mm

Thickness: 2-30 hli

Qhov ceev: 0.38-0.8g / cm3

Cov zis: 550-600kg / h lossis 700kg / h, nws nyob ntawm qhov kev xaiv ntawm extruder.Kuj tuaj yeem ua co-extrusion ntawv / board tshuab .

ENVIRONMENTAL CONDITION:

| Qhov chaw | Hauv tsev |

| Fais fab mov | Tsis muaj chaw txaus ntshai |

| Cov av noo | ≤ 95% |

| Kub | 0-40 ºC |

| Hwj chim | 3-theem, 380V, 50Hz |

| Tag Nrho Cov Hluav Taws Xob | <300 KW |

| Dej txias | ≤25ºC ≥0.3MPa, sab nraum zoov dej tank: 20-30m3, dej ncig nrog cov kab ntau lawm |

| Cua compressed | 0.3 m³ / min,> 0.5MPa, Nruab nrog 5.5-7.5kw cua compressor |

| Ntau lawm kab Dimension | Luas = 25 m x 3 m |

Flow daim ntawv qhia:

Tov khoom → Loader → Extruder → Pwm → Calibration platform → Cooling bracket → Hauling tshuab → Txiav tshuab (nrog plua plav collector) → Stacker

→ Ntim → Crusher (rau cov khoom pov tseg) → Pulverizer (Rau cov khoom siv rov ua dua)

Q1: Koj lub tuam txhab yog lub tuam txhab lag luam lossis lub tshuab tsim khoom?

A1: Peb lub tuam txhab yog cov chaw tsim khoom yas uas tau koom nrog hauv kev lag luam no ntau tshaj 10 xyoo.Raws li cov chaw tsim khoom, peb tuaj yeem muab peb lub tshuab, kev pabcuam, kev txhawb nqa thiab kev saib xyuas ncaj qha thiab nws yooj yim dua.

Q2: Yuav ua li cas thiaj tau txais qhov kev lees paub tseeb?

A2: Vim tias peb qhov kev thov thiab kev qhia tshwj xeeb yog cuam tshuam nrog koj cov khoom kawg thiab thov kom muaj peev xwm, peb yuav xaiv tus qauv zoo ntawm extruder thiab pwm tom qab nkag siab tag nrho cov ntaub ntawv, ces peb tuaj yeem muab peb txoj kev npaj.Peb tuaj yeem hloov pauv cov ntaub ntawv los ntawm Email, whatsapp. los yog wechat.

Q3: Koj lub Hoobkas nyob qhov twg thiab qhov chaw nres nkoj twg nyob ze rau koj lub Hoobkas?

A3: Kuv lub Hoobkas nyob hauv Qingdao nroog, xeev Shandong thiab nws yuav siv sijhawm li 25 feeb los ntawm peb lub Hoobkas mus rau Qingdao jiaodong tshav dav hlau.

Qhov chaw nres nkoj ze tshaj plaws yog Qingdao chaw nres nkoj.

Q4: Lub sijhawm khoom xa tuaj ntev npaum li cas?

A4: Feem ntau nws yuav siv sijhawm 35-45 hnub.

Q5: Koj puas tuaj yeem xa koj cov engineers tuaj rau peb lub Hoobkas?

A5: Yog lawm, peb yuav xa peb cov engineers mus rau koj lub Hoobkas rau kev teeb tsa, kev ua haujlwm thiab kev cob qhia tom qab cov tshuab tuaj txog ntawm koj lub Hoobkas.Ntxiv, yog tias koj xav tau peb cov engineers muaj nyob rau yav tom ntej, peb kuj tuaj yeem xa peb cov engineers.

Post lub sij hawm: May-15-2023