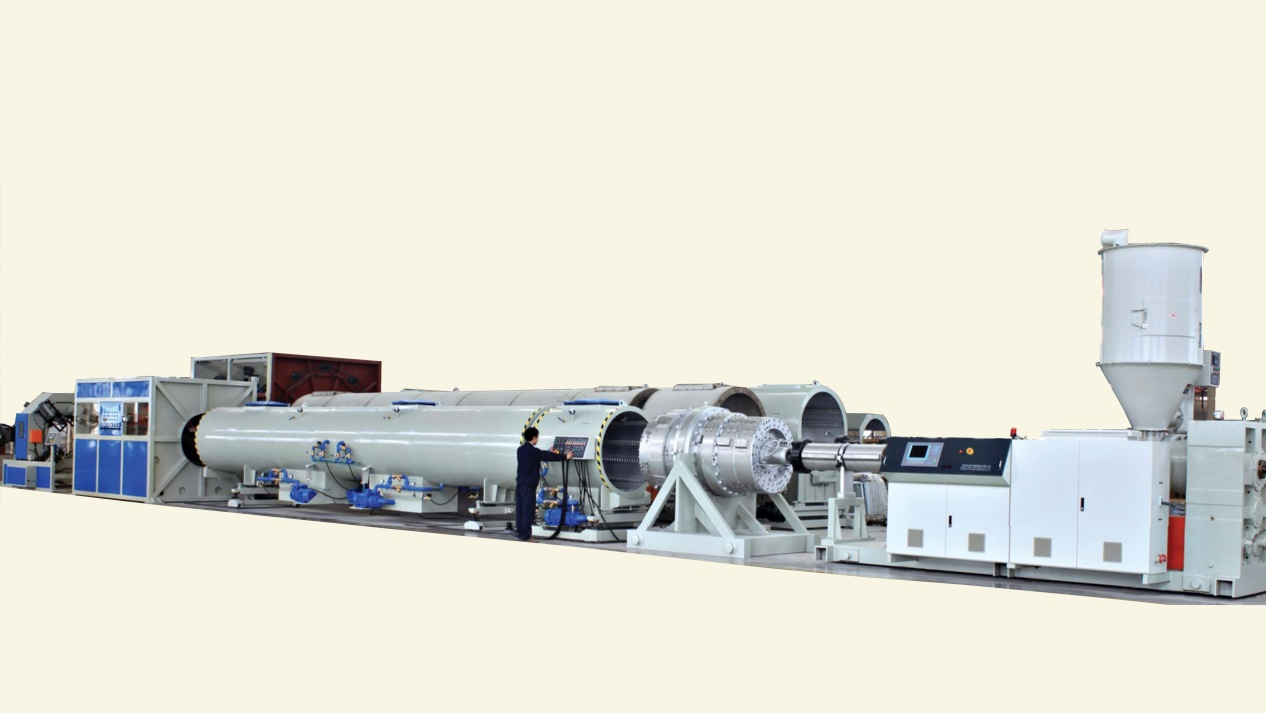

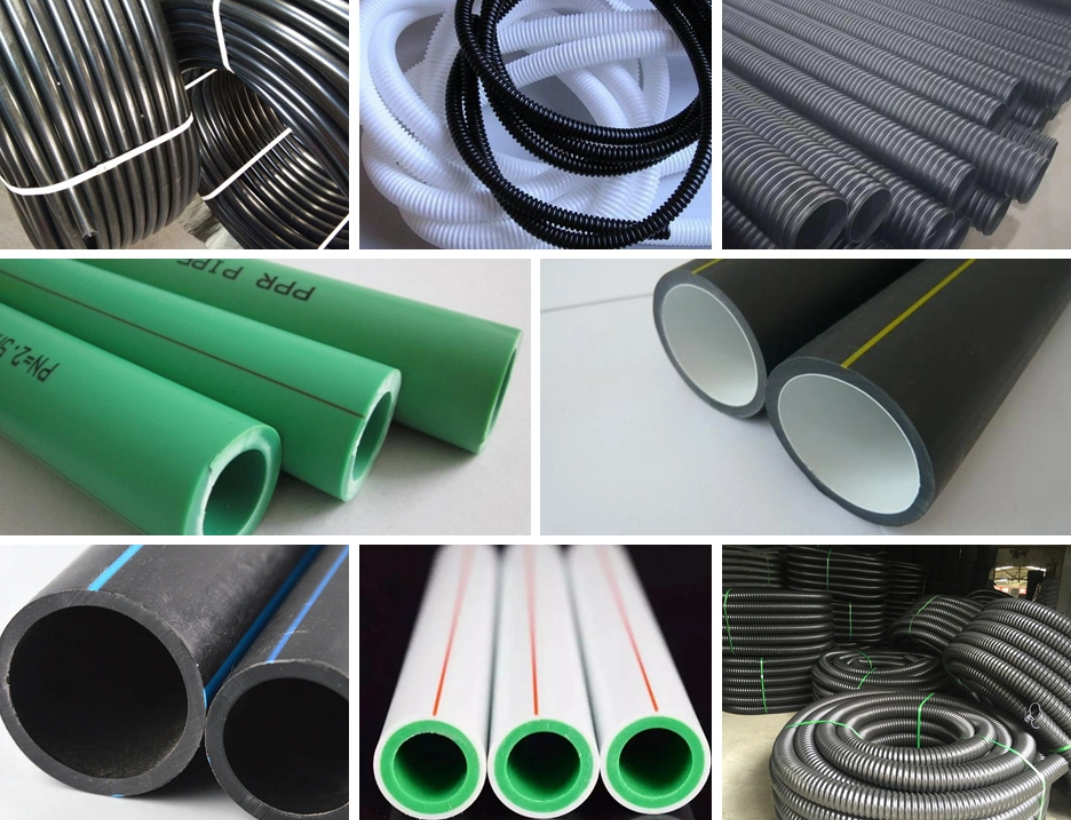

1.PE yeeb nkab Extrusion tshuabyog siv los ua cov kav dej ua liaj ua teb, cov kav dej, cov kav dej, cov kav dej, cov kav dej, cov kav dej cable thiab lwm yam.

>> Cov yeeb nkab muaj qee yam zoo heev xws li cua sov resistant, aging resistant, siab mechanical zog, ib puag ncig kev nyuaj siab tawg resistant, zoo creep resistant, thiab lwm yam. suab nrov, Gravimetric dosing unit thiab ultrasonic thickness qhia tuaj yeem sib sau ua ke raws li cov neeg siv khoom xav tau kom nce qhov tseeb ntawm cov kav dej.

>> Tig cov tshuaj tseem ceeb tuaj yeem muab tau, xws li laser tshuab luam ntawv crusher, shredder, dej chiller, cua compressor thiab lwm yam. kom ua tiav qib siab thiab tsis siv neeg raj ntau lawm.

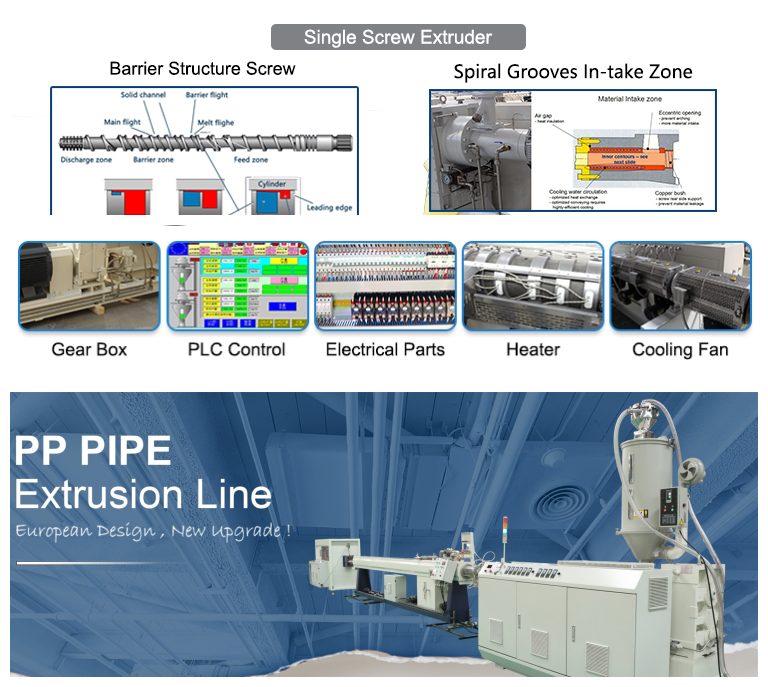

Txheej Txheem Flow:Raw khoom + Master Batches → Sib tov → Nqus Feeder → Yas Hopper Drier → Ib leeg ntsia hlau extruder → Co-extruder rau xim hlua & Ntau txheej → Pwm → Nqus calibration Tank → Txias Txias Dej Tank → Haul-off → Tsis muaj plua plav Cutter → Ob chav / Ib leeg disc Winding / Stacker → Cov khoom kawg tshawb xyuas & ntim

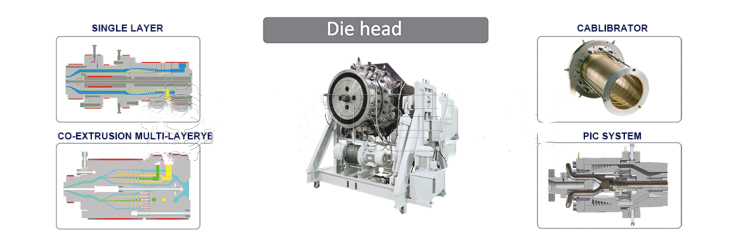

2.PE yeeb nkab tuag taub hau

Post lub sij hawm: Aug-31-2023